Everything you need to know about the GFRG Panel in Building Construction

GFRG Panel Construction: A Technological Advancement in Construction Industry

In India, there is a huge requirement for building materials due to the existing housing shortage mainly in urban India. And till date, it takes a lifetime worth of savings to buy a house. And most of us who buy the houses from their lifetime savings have to pay the EMIs till their retirement age. To overcome this housing hurdle, India needs innovative, high-efficiency building materials for strong and durable housing in an advanced mode of construction at an affordable cost. All these issues and concerns are required in sustainable and overall development. GFRG Panel provides speedy construction and contributes to environmental protection.

There have been a lot of efforts made earlier by the industry experts to find an alternative to existing construction technology to make it more affordable. Glass Fibre Reinforced Gypsum (GFRG ) is one such technology in the construction field that could reduce the construction cost by 50% or more.

About GFRG Panel

The word GFRG signifies Glass Fibre Reinforced Gypsum which is also recognized as Rapid Walls. It is made up of high strength resistant glass fibers bonded with high-density gypsum cement. It was invented in 1990 by the GFRG Building System Australia. Now, this method of construction is broadly accepted by a few Asian nations such as India, Saudi Arabia, Oman, and China.

Glass Fiber Reinforced Gypsum (GFRG) Panel is a modern building component used for mass-scale construction of houses in a very short span of time. This is a technological advancement in the construction Industry. They are basically white in color and have a glazy surface. They are energy-efficient green building material with enormous potential for use as load-bearing and non-load bearing wall panels. It is suitable for the construction of both external and internal walls. It can also be used as an intermediary floor slab/roof slab together with Reinforced Cement Concrete (RCC) as a composite material. Not only the walls, but the floors, sunshades, boundary, roofs and the walls can also be made using GFRG panels.

Glass Fiber Reinforced Gypsum (GFRG) Panel is a modern building component used for mass-scale construction of houses in a very short span of time. This is a technological advancement in the construction Industry. They are basically white in color and have a glazy surface. They are energy-efficient green building material with enormous potential for use as load-bearing and non-load bearing wall panels. It is suitable for the construction of both external and internal walls. It can also be used as an intermediary floor slab/roof slab together with Reinforced Cement Concrete (RCC) as a composite material. Not only the walls, but the floors, sunshades, boundary, roofs and the walls can also be made using GFRG panels.

GFRG panel possesses high flexural strength, shearing strength, compressive strength, and flexibility. It has a very high level of resistance to fire, water, heat, corrosion, rot, and termites. Concrete filled with vertical reinforcement rods improves it’s vertical and lateral load capacities. GFRG made buildings are resistant to fire, earthquakes, and cyclones.

After the foundation is placed applying the advanced method, these GFRG panels are being set on the foundation with the help of cranes. A unique locking system is being used to grip the ribs of the panel on top. This kind of wall does not require any plastering.

How does GFRG Technology work?

GFRG Panels being placed on plinth using Crane. It essentially replaces the use of blocks/bricks for constructing the structure of the house/building. These are nothing but prefabricated Gypsum Boards reinforced with Glass Fibres. The panels are manufactured at factories and brought at the site directly and fixed on the structure like a lego system. Once a foundation is laid, these panels are erected on the foundation with the help of cranes. Besides, it does not need plastering and painting as a normal wall would need.

Why GFRG?

GFRG houses are:

- Fire-resistant up to 1000°C

- Earthquake resistant

- Naturally cooler up to 4°C

- Eco-Friendly

- Water-resistant

- Economical

GFRG Material Cost

GFRG Panel cost is around Rs 999/sq.m. while introduced in India in the year 2018 but now after adding the GST of 12%, its current price is Rs 1120. Price may vary from state-to-state.

Is GFRG Panels a government accepted material for building constructions?

Of course, it is an approved and accepted construction material by the Building Material and Technology Promotion Council of India (BMTPCI).

How does GFRG technology reduce the cost of construction?

- The main component that is being used to make the construction panel is a powder. It is a leftover of many fertilizer industries and is available at a very cheap rate in the local market.

- It is very easy to assemble and doesn’t require a long drying time, thus resulted in less construction time.

- Offering cheaper alternatives than concrete and bricks for construction.

- Reduction in overall construction duration saves labor costs.

Physical & Material Properties

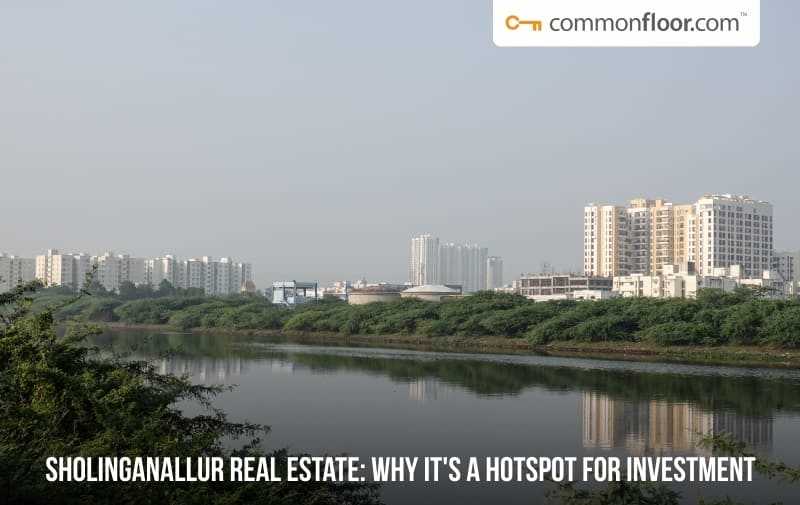

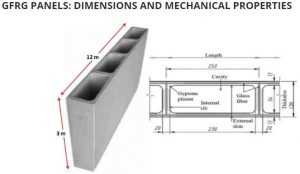

GFRG Panel is the world’s largest lightweight load-bearing panels manufactured with a size 12m length, 3m heights, and 124mm thickness. Each panel has 48 modular holes of 230 mm * 94mm * 3m dimension. The weight of one panel is 1440 kg.

The physical and material properties of each panel are as follows:

| Mechanical Properties | Dimension |

| Unit Weight | 1440 kg |

| Compressive Strength | 73.2 kg/cm2 |

| Flexural Strength | 21.25 kg/cm2 |

| Tensile Strength | 35 KN/m |

| Ductility | 4 |

| Thermal Resistance R | 0.36 K/W |

| Thermal conductivity | 0.617 |

| Sound Transmission | 40 |

| Axial Load capacity | 16 tons/m |

| Unit Shear Strength | 50.90 kN/m |

| Fire Resistance | 700-1000*C (up to 140 min) |

| “U” Value | 2.85 W/M2K |

| Elastic Modulus | 3000-6000 Mpa |

| Water Absorption | <5% |

What are the advantages and disadvantages of GFRG Panel Construction?

Advantages of GFRG Panel

- Rapid Construction’

- More carpet area for the same built-up area;

- Less included the energy and carbon footprint, an essential reduction in the use of steel, sand, cement, and water;

- Less construction cost;

- Less building weight, hence reduction in design for seismic forces and savings in the foundation, especially in multi-storeyed buildings;

- One can construct 8 to 10 storeyed buildings using GFRG Panels;

- It gives a smooth finishing;

- It releases less Co2 compared to other traditional building materials;

- GFRG Panel made building gives better thermal comfort inside in winter season

GFRG Panel Disadvantages

- It requires more space for the movement of a crane during the construction time.

- It makes the construction method less cost-effective since the design of the GFRG Panel is complicated.

- For installing the GFRG panels, highly experienced and skilled labor is needed

- During the transportation and erection process, the GFRG Panel should be handled carefully.

- To cut the GFRG Panel at the site, it requires specific machinery.

- GFRG panels can’t be used for the construction of walls in circular or in curve shape.

Is this technology safe? And how long the GFRG Panels constructed house last?

Yes, the houses made by GFRG Technology are as strong as a traditionally constructed house. These houses have a life of more than 100 years. Although, this technology is new to India but long used in Australia and considered to be one of the safer options. The GFRG panels made houses are fire resistant and earthquake resistant.

The design and construction of important structural elements

GFRG Buildings Design and Construction

GFRG Panel system building designed as a load-bearing system. Hence, all walls are constructed from the foundation or plinth beam till the terrace. Most suitably the same floor plan has to be replicated for all floors in multi-story buildings and it can be designed up to 10 storeys in low seismic zones using GFRG panels without taking the help of the conventional columns and beams.

The GFRG building construction is not the same as a traditional system. It needs specific equipment, tools, and tackles such as a proper crane for loading, unloading and setting the panels, lifting clamps and spreader bars for uplifting the panels and resetting the prop later for supporting wall panels after erection.

Foundation Design & Construction

In GFRG building constructions, the conventional type of foundations is used. It is designed based on the safe bearing capacity of soil and soil profile at the particular site and the number of storeys of the structure.

Normally, strip footing is used, as the superstructure consists of load-bearing walls. For low-rise GFRG buildings, simple masonry developed footings is enough with a chain of reinforced concrete (RC) plinth beams on top, above which the GFRG wall panels can be set.

GFRG Wall Design and Construction

The GFRG walls are designed to resist axial force from gravity loads, lateral in-plane shear force and in-plane bending moment from wind and seismic loads. The in-plane bending capacity of the wall depends on its length, the reinforcement is given, as well as the level of axial load and lateral shear. The values of mud and in-plane shear strength increase with the length of the wall.

Design interaction curves are formed for various lengths of GFRG panels (from1.0 m to 3.5 m wide) based on the structural requirements and the design interaction curves, the interval of concrete infilling and the size of reinforcement to be provided in walls are decided. The cavities in the GFRG wall panels shall be filled, wherever structurally required, with concrete of grade not less than M20, using an aggregate of size less than 12mm.

For up to 3 storeyed high low rise GFRG buildings there is no need to infill all cavities with reinforced concrete.

The GFRG panel building can be constructed fast using the crane. It is advisable to erect the panels without removing door/ window cut pieces from the panel. This will keep the panel in balance and help to locate the center of gravity of the wall panel. Once the panel is brought in position, the plumb and level are to be checked. These props can be removed once the panels are in-filled with concrete and gain sufficient lateral stability.

Staircase Design and Construction

GFRG panels can be utilized for the construction of staircase waist slabs. All the top flanges of panels shall be cut open and the reinforcement cage is to be inserted. This can be concreted after providing appropriate support. The steps can be constructed with either concrete or bricks.

Applications of GFRG Panel in Building Construction

For Load Bearing Walls

For load-bearing walls: One of the most common applications of GFRG panels is observed as load-bearing structures in the buildings. When the cavities inside the GFRG panels are filled with concrete, the compressive strength of the panels gets enhanced. Additionally, when the reinforcing bars are introduced, the ability of the panel to resist the lateral loads also gets enhanced. Henceforth, using such load-bearing structures in the construction is the most suitable option for multistoried buildings.

Partition Walls

GFRG panels can also be used as partition in-fill walls in single or multi-storied buildings. Such panels are used as partition walls, whereas these panels can also be used for cladding in industrial buildings or sports ground. Likewise, they can also be used as compound walls or security walls.

Horizontal Floor and Roof Slabs

GFRG panels for floor and slab are cut to the required size and it’s marked with notations. Firstly, the wall joints, cavities, and the horizontal RCC tie beams are filled with concrete. Thereafter, a wooden plank of width 300 mm to 450 mm is provided to room span between the walls with support wherever the embedded microbeams are present. Finally, roof panels are to be lifted by the crane so that the panel can float perfectly horizontal. Each of the GFRG roof panels is placed over the wall in such a way that a minimum gap of 40 mm is provided.

Step-By-Step Construction Using GFRG Panels

Excavation and Foundation Work

Excavation of soil is executed in the same way to lay the foundation. Once the foundation is placed, the waterproofing of the foundation is fulfilled by spraying suitable chemicals.

Placing panels

The casting of reinforced concrete is laid down for the plinth beams. Then the starter bars are set inside the concrete casting so that the GFRG panels can be installed. They are put on the starter bars according to the dimensions and the areas allotted to them. Once they are set, waterproofing is given for protecting the joints.

Pouring concrete

After fixing the GFRG panels, they must be held in place until the concrete mixture is poured on them. The support bars provide support to these panels. After that, the concrete mix is filled into each of the holes of panels from the top.

Placing slabs

After finishing the walls, the panels are placed on the top as slabs. A reinforcement cage for the set beams is fitted and concrete screed is provided by pouring concrete mix on the slab.

Image source: Google